6-20 个字符(仅限字母加数字)

密码不一致

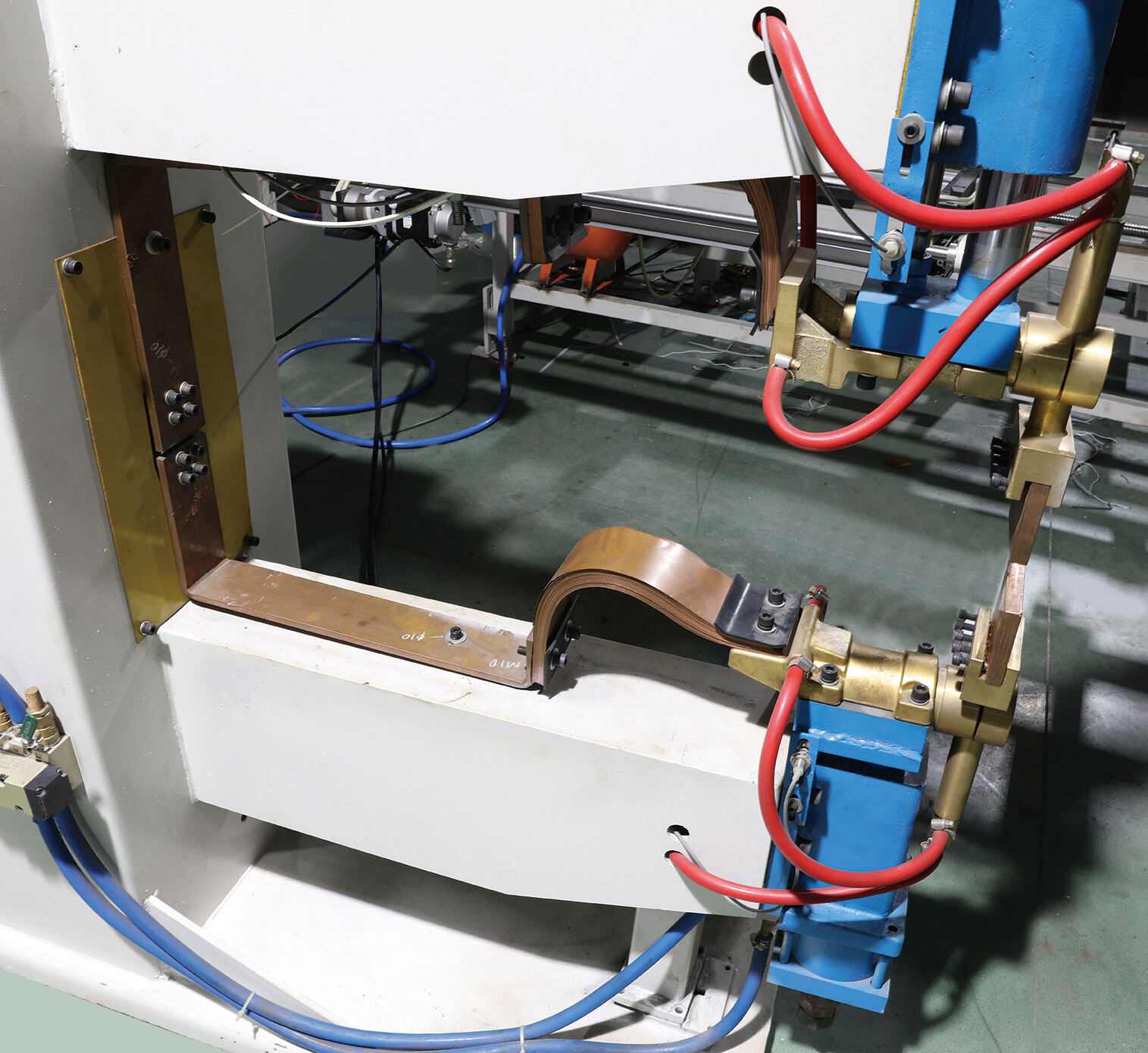

中国逆变焊机

Inverter welding and cutting equipment consists of inverter power supply and external equipment. The inverter power supply is the core of the inverter welding and cutting equipment. Its working process is: power frequency AC-DC-high frequency AC-transformer-DC, which is obtained by rectifying and filtering three-phase or single-phase 50Hz power frequency AC power For smoother direct current, the inverter circuit composed of IGBT or FET converts the direct current into 15-100kHz alternating current. After the intermediate frequency main transformer is stepped down, it is rectified and filtered again to obtain a stable DC output welding current (or inverter again). output alternating current of the desired frequency).

The control circuit of the inverter welding and cutting equipment is composed of a given circuit and a drive circuit. By processing the feedback of the voltage and current signals, the whole machine can be controlled in a cycle, and the pulse width modulation PWM is used as the core control technology, so as to obtain a fast pulse. Widely modulated constant current characteristics and excellent welding and cutting process effect.

Due to the high operating frequency of the inverter, the cross-sectional area of the core and the number of coil turns of the main transformer are greatly reduced. Therefore, the inverter welding machine can save metal materials to a large extent, reduce the size and weight, and greatly reduce the power loss. What is important is that the inverter welding machine can adjust the output current in microseconds, so it can realize the ideal control process required by the welding process and obtain satisfactory welding results.